Woodworker's Journal 2004 Summer, страница 10

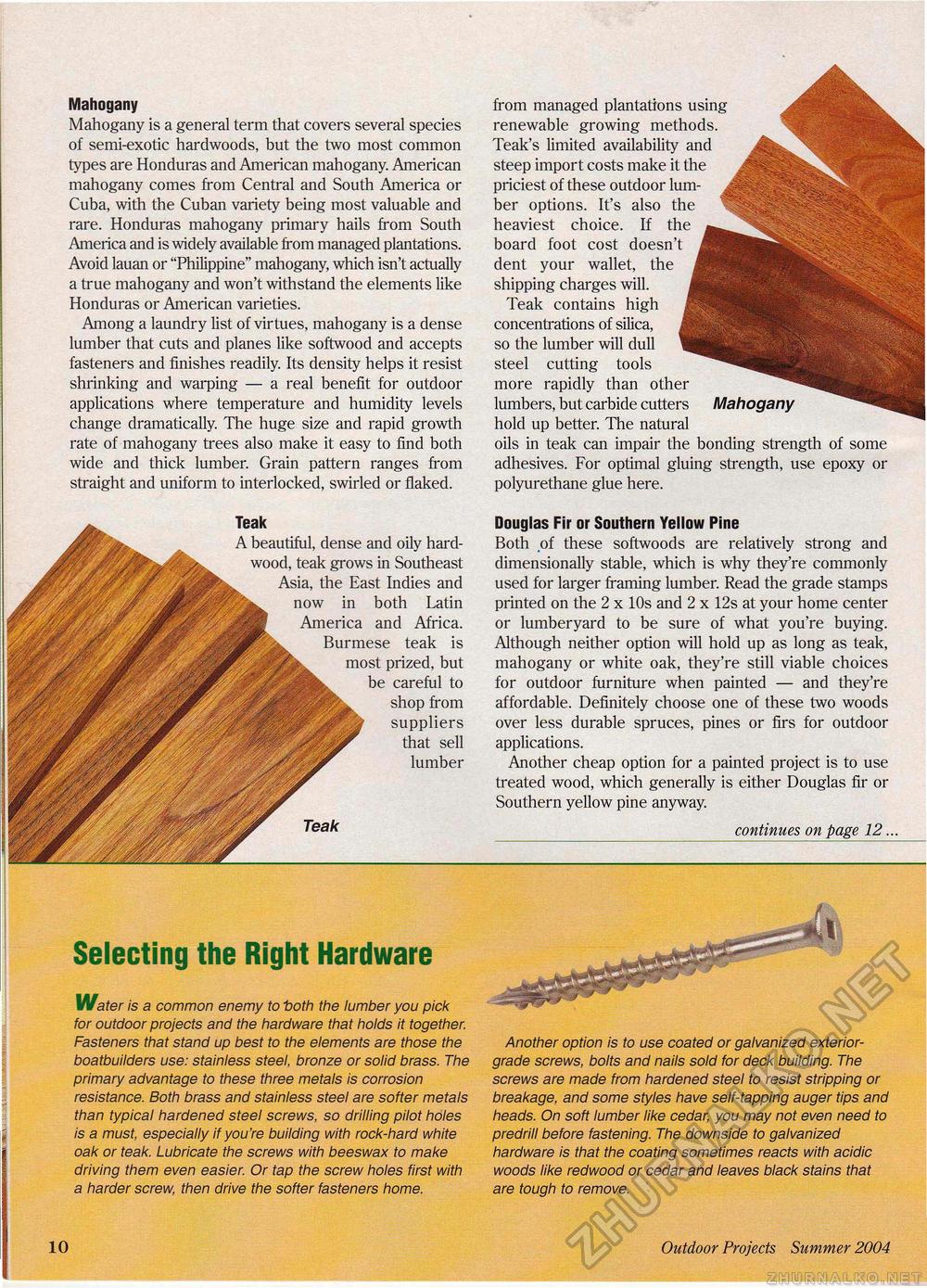

Mahogany Mahogany is a general term that covers several species of semi-exotic hardwoods, but the two most common types are Honduras and American mahogany. American mahogany comes from Central and South America or Cuba, with the Cuban variety being most valuable and rare. Honduras mahogany primary hails from South America and is widely available from managed plantations. Avoid lauan or "Philippine" mahogany, which isn't actually a true mahogany and won't withstand the elements like Honduras or American varieties. Among a laundry list of virtues, mahogany is a dense lumber that cuts and planes like softwood and accepts fasteners and finishes readily. Its density helps it resist shrinking and warping — a real benefit for outdoor applications where temperature and humidity levels change dramatically. The huge size and rapid growth rate of mahogany trees also make it easy to find both wide and thick lumber. Grain pattern ranges from straight and uniform to interlocked, swirled or flaked. from managed plantations using renewable growing methods. Teak's limited availability and steep import costs make it the priciest of these outdoor lumber options. It's also the heaviest choice. If the board foot cost doesn't dent your wallet, the shipping charges will. Teak contains high concentrations of silica, so the lumber will dull steel cutting tools more rapidly than other lumbers, but carbide cutters hold up better. The natural oils in teak can impair the bonding strength of some adhesives. For optimal gluing strength, use epoxy or polyurethane glue here. Mahogany Selecting the Right Hardware Teak A beautiful, dense and oily hardwood, teak grows in Southeast Asia, the East Indies and now in both Latin America and Africa. Burmese teak is most prized, but be careful to shop from suppliers that sell lumber Teak Douglas Fir or Southern Yellow Pine Both of these softwoods are relatively strong and dimensionally stable, which is why they're commonly used for larger framing lumber. Read the grade stamps printed on the 2 x 10s and 2 x 12s at your home center or lumberyard to be sure of what you're buying. Although neither option will hold up as long as teak, mahogany or white oak, they're still viable choices for outdoor furniture when painted — and they're affordable. Definitely choose one of these two woods over less durable spruces, pines or firs for outdoor applications. Another cheap option for a painted project is to use treated wood, which generally is either Douglas fir or Southern yellow pine anyway. continues on page 12... A Ml Water is a common enemy to both the lumber you pick for outdoor projects and the hardware that holds it together. Fasteners that stand up best to the elements are those the boatbuilders use: stainless steel, bronze or solid brass. The primary advantage to these three metals is corrosion resistance. Both brass and stainless steel are softer metals than typical hardened steel screws, so drilling pilot holes is a must, especially if you're building with rock-hard white oak or teak. Lubricate the screws with beeswax to make driving them even easier. Or tap the screw holes first with a harder screw, then drive the softer fasteners home. tffiSBiirti Another option is to use coated or galvanized exterior-grade screws, bolts and nails sold for deck building. The screws are made from hardened steel to resist stripping or breakage, and some styles have self-tapping auger tips and heads. On soft lumber like cedar, you may not even need to predrill before fastening. The downside to galvanized hardware is that the coating sometimes reacts with acidic woods like redwood or cedar and leaves black stains that are tough to remove. 10 Outdoor Projects Summer 2004 £ |